Ceramic

Ceramic tubular membranes inside/out filtration

The cross-flow filtering configuration with a ceramic tubular membrane is suggested for “difficult” applications. In some applications it was possible to treat solutions of up to 15% of suspended solids and residues.With the available tubular channels of dimensions 2 to 14 mm in diameter, the filtering membrane allows to:

- Treat liquids with high concentrations of suspended solids

- Treat highly polluting fluids

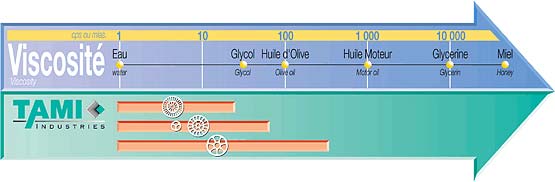

- Treat high viscosity liquids (see figure)

In some applications it was possible to treat solutions of up to 15% ofsuspended solids and residues.

Ceramics are also extremely suitable for applications involving: hightemperatures, acids, bases and solvents. Elementsare manufactured using various materials in order to cover a widerrange of applications:

- Support in titanium oxide and active layer in zirconium oxide

- Support in titanium oxide and active layer in titanium oxide

- Support in titanium oxide and active layer of varying thickness

Thanks to its high chemical and mechanical strength, a ceramic membrane thatsuffers from fouling and therefore reduced permeability can be regenerated using cleansing cycles with parallel flow to the concentrate flow.

However,the fouling thickness can be controlled using compressed air in orderto increase the time between chemical cleaning cycles. This is doneto maximize the time of membrane operation.

Ask for information