Membrane per Filtrazione Tangenziale

Sepra rende disponibile una ampia gamma di elementi a membrana per i processi di filtrazione tangenziale. Siamo infatti in grado di lavorare con mezzi filtranti diversi (polimerici ed inorganici):

- MEMBRANE POLIMERICHE A SPIRALE AVVOLTA

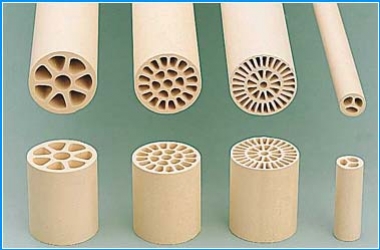

- MEMBRANE CERAMICHE TUBOLARI

- MEMBRANE POLIMERICHE A FIBRA CAVA

- MEMBRANE POLIMERICHE TUBOLARI

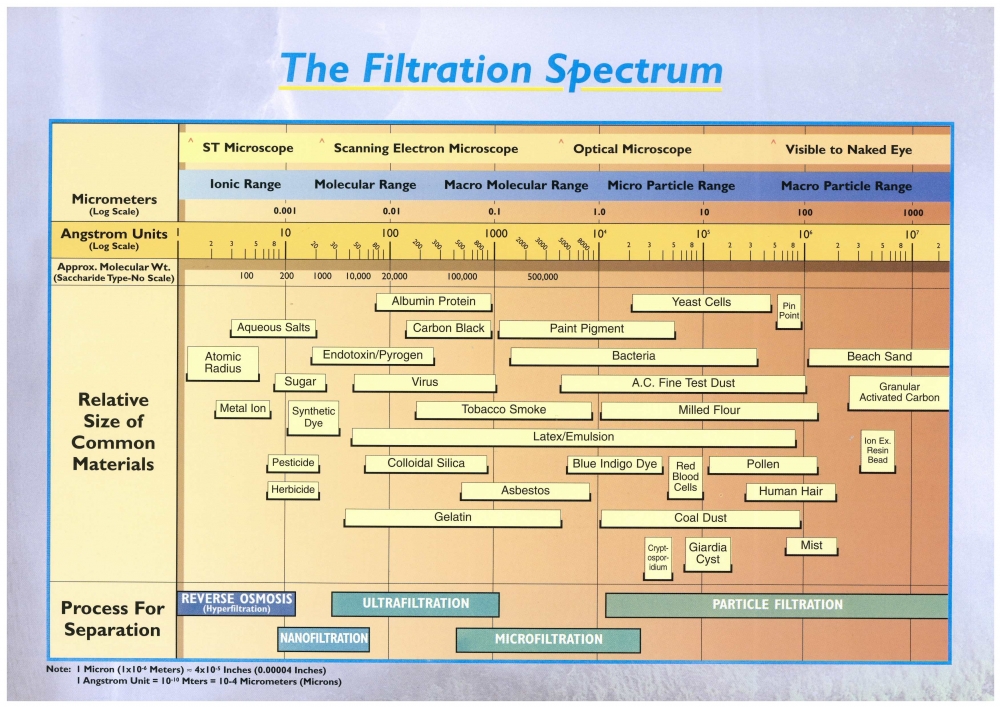

Il campo dei processi di filtrazione coperto spazia dalla microfiltrazione all'osmosi inversa, passando per la ultrafiltrazione e la nanofiltrazione.

Membranes never enough for us.

Chiedici informazioni